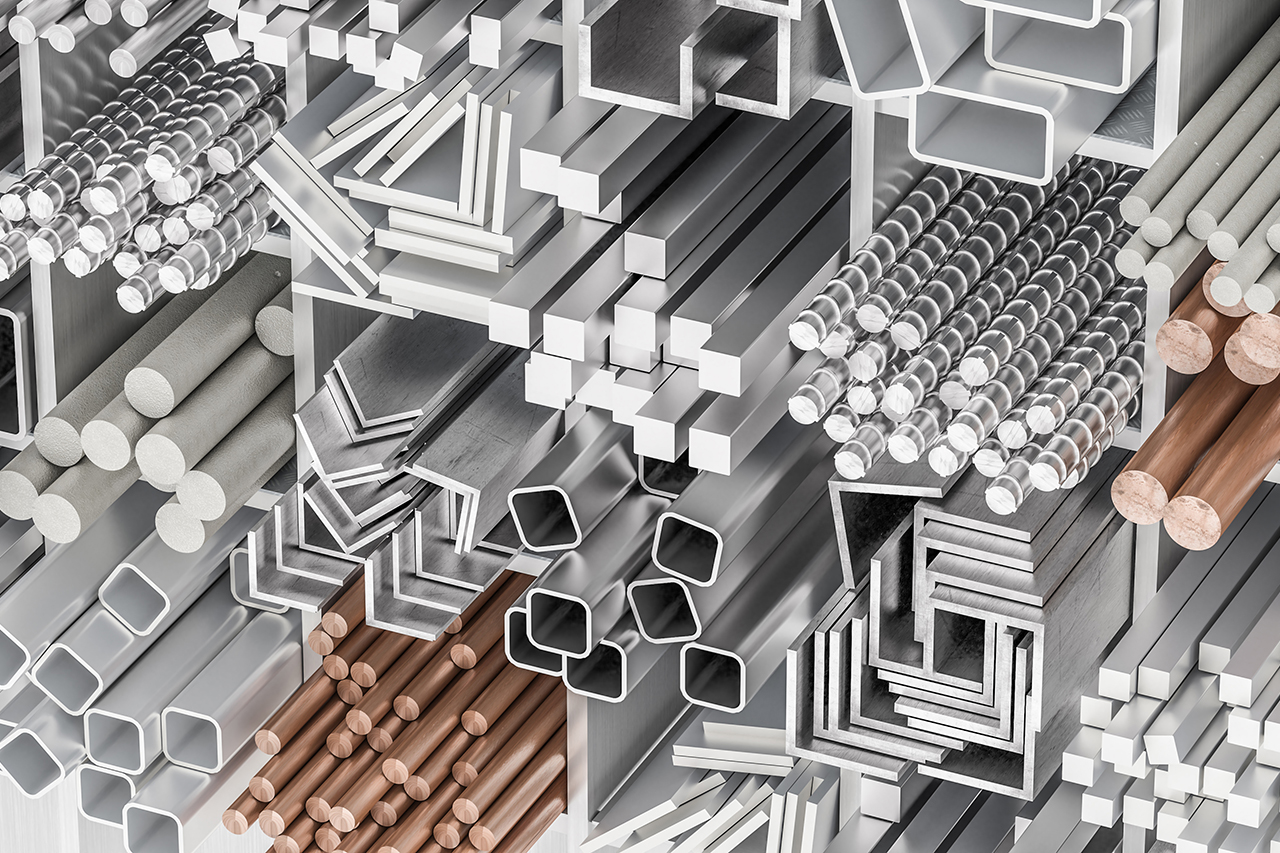

Metal fabrication is a noble industry without which society and the development of other industries would hardly move a step. Thanks to metal working machines and the production of engineering semi-finished products, various other products and custom-made parts are created that are needed to carry out assemblies, installation work and much more. You could say that metal fabrication is the basis for building almost everything around us.

Our company is dedicated to the production of custom-made engineering semi-finished products. With modern machinery and our own facilities, we can produce a variety of common and atypical parts for your production. Welded structures, bent profiles or precision turning and milling according to requirements is no problem for us.

Welded structures

Welding technology works on the system of joining two fusible materials. Welding uses local melting of metals, followed by fusion and cooling. The resulting joint is called a weld. There are several forms of welding, which differ in the process, the type of materials (different metals and aluminium) or even the thickness of the materials. The basic division is into fusion and pressure. Fusion welding uses local welding of materials without the use of pressure. It is further differentiated only by the heating method. Pressure welding follows the same procedure, except that external pressure is also required. The weld may be further machined to increase its strength or ground to make the surface smooth. However, care must always be taken with the quality of the welds. At DAVOS trade-logistics, we weld both aluminium and copper and produce custom welded metal structures. After consulting with the customer and evaluating the strength and quality of the design, we will custom weld almost anything.

Profile bending

Bending presses are used to bend profiles to various radii and can effectively bend metals to requirements. We use the TRUMPF TruBend 5320 bending press - 320 t / 3200 mm. This press is one of the best and highest quality equipment currently available on the market. Thanks to the precision capabilities and quality of our machine, we can manufacture products and parts exactly to your specifications and can even fulfil more demanding projects after consultation.

Division of materials

When cutting materials, it is necessary to be professional and precise to avoid unnecessary damage. The material to be cut should therefore always be measured several times before it is cut, sheared or sawed. Care must therefore be taken to prepare the material thoroughly before dividing it. We use professional TRUMPF (EHT) EcoCut 13-30 shears to cut the material, which cut the metal material with the utmost precision, so you don't have to worry about deviations and inaccuracies. For harder metals, we use a BOMAR band saw, which has no problem with any metal and its precision is of course also at a high level.

Precision turning

Turning is chip machining of materials (metals, wood, plastic). Quality and precision are important in turning. This is exactly why we use the DOOSAN Puma 2100LM CNC lathe. This fully programmable modern CNC lathe works with high precision and we can create various metal products exactly according to your design and plans. You can rely on precision and quality, as we pride ourselves on it and carry out turning honestly down to the smallest detail.

Precision milling

Milling is the mechanical machining of a material where the material is cut by a rotary motion on a milling cutter. It is mainly used for machining planar and shaped surfaces.

For precision milling we use the FEELER NBP 1300A CNC milling machine - table 1300 x 600 mm, thanks to which we are able to mill the material with precise detail down to the smallest detail.

Metal fabrication and the production of engineering blanks can truly be likened to an industrial art, as they need to be carried out with precision and sensitivity. Bespoke parts are the one thing that no other production would move forward without, which is why you should think quality above all else when making your purchase.